Ready to Start?

Production-quality flex and rigid flex prototypes and small-to-medium-production at quick-turn speeds. Leading-edge technologies to fabricate your designs to validate concepts to production.

Enquire

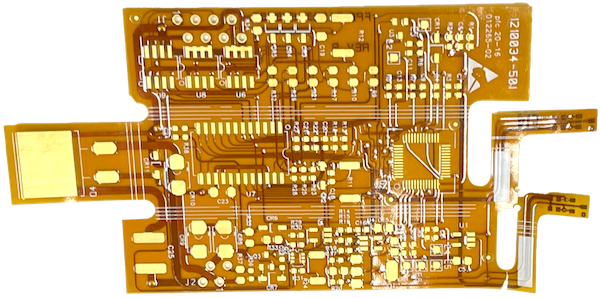

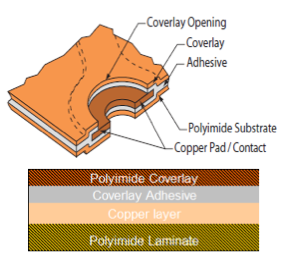

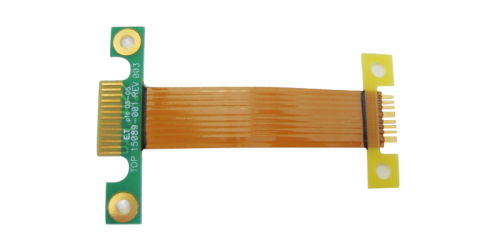

Single-sided flex circuits are the most basic type of flexible circuits. They have one layer of copper laminated between polyimide dielectrics. We chemically etch the copper layer to produce a circuit pattern specific to design requirements. Stiffeners, pins, connectors, and components, are optional. Single-sided flex circuits are durable across applications and are excellent for installations in small spaces.

Complete assembly

SMT and/or through- hole

Simplified design and manufacturing

Dynamic flexing applications

Minimized interconnect errors

Production-quality flex and rigid flex prototypes and small-to-medium-production at quick-turn speeds. Leading-edge technologies to fabricate your designs to validate concepts to production.

Enquire

Double-sided circuits have two layers of copper laminated between polyimide dielectrics.

Learn More

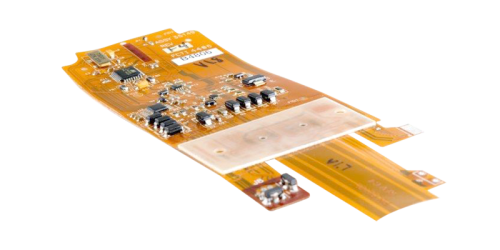

Multi-layer flexible circuits combine several single-sided or double-sided circuits with complex interconnections, shielding and/or surface mounted technologies in a multi-layer design.

Learn More

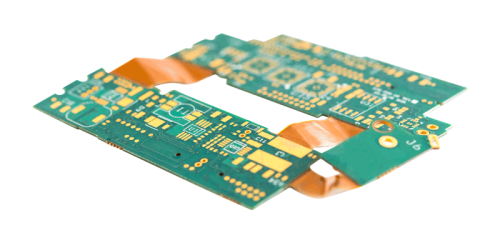

Rigid flex circuits combine the benefits of rigid boards and flexible circuits integrated into one circuit.

Learn More

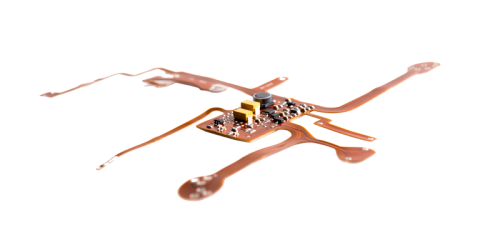

Sculpted flexible circuits have sculpted pins, often chosen to eliminate the need and cost of a ZIF connector.

Learn More

PFC has created the PFC High Speed Data Link Flexible Circuits product line, in collaboration with Samtec.

Learn MoreProduction-quality flex and rigid flex prototypes and small-to-medium-production at quick-turn speeds. Leading-edge technologies to fabricate your designs to validate concepts to production.