Ready to Start?

Production-quality flex and rigid flex prototypes and small-to-medium-production at quick-turn speeds. Leading-edge technologies to fabricate your designs to validate concepts to production.

Enquire

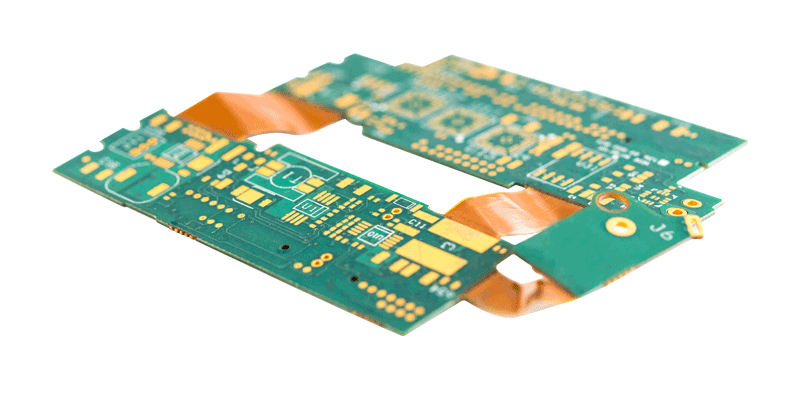

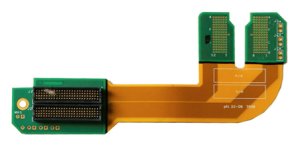

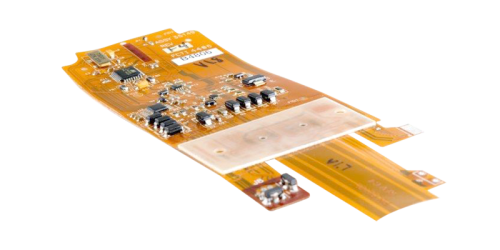

Rigid flex circuits combine the benefits of rigid boards and flexible circuits integrated into one circuit. The two-in-one circuit is interconnected through plated through holes. Rigid flex circuits provide higher component density and better quality control. The slideshow below shows an eight layer rigid flex circuit used for a medical device. Four layers are rigid and four layers are flexible. There are connectors required on two different sides of the circuit, which is carrying signals and power.

Improved connectivity and signal integrity

Allows for placement of fine-pitch components and small components

Meets double-sided assembly requirements

Production-quality flex and rigid flex prototypes and small-to-medium-production at quick-turn speeds. Leading-edge technologies to fabricate your designs to validate concepts to production.

Enquire

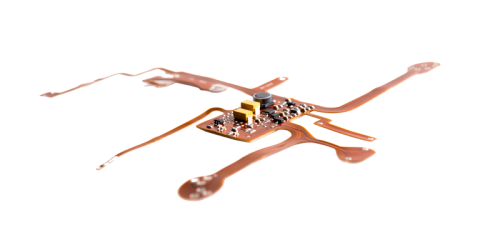

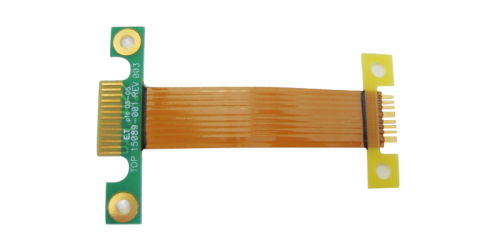

Single-sided flex circuits are the most basic type of flexible circuits, durable across applications and are excellent for installations in small spaces.

Learn More

Double-sided circuits have two layers of copper laminated between polyimide dielectrics.

Learn More

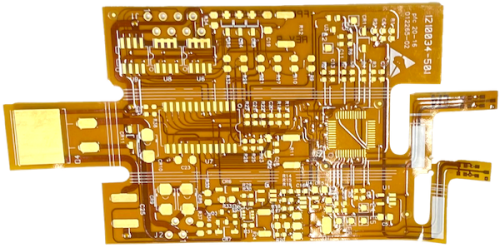

Multi-layer flexible circuits combine several single-sided or double-sided circuits with complex interconnections, shielding and/or surface mounted technologies in a multi-layer design.

Learn More

Sculpted flexible circuits have sculpted pins, often chosen to eliminate the need and cost of a ZIF connector.

Learn More

PFC has created the PFC High Speed Data Link Flexible Circuits product line, in collaboration with Samtec.

Learn MoreProduction-quality flex and rigid flex prototypes and small-to-medium-production at quick-turn speeds. Leading-edge technologies to fabricate your designs to validate concepts to production.