Ready to Start?

Production-quality flex and rigid flex prototypes and small-to-medium-production at quick-turn speeds. Leading-edge technologies to fabricate your designs to validate concepts to production.

Enquire

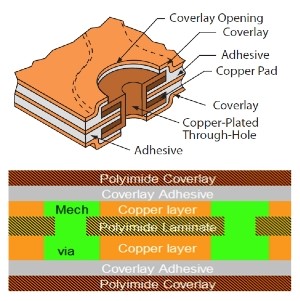

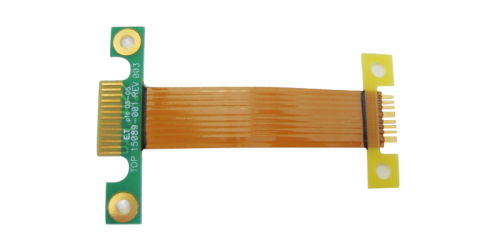

Double-sided circuits have two layers of copper laminated between polyimide dielectrics. In most cases, the two layers of copper are electrically connected by drilling small holes through the copper circuits and the separating dielectric. The holes are then plated with copper to make a connection between them. The slideshow below shows the artwork required for each layer of the circuit build.

Wider circuit design parameters

Access to circuit traces from both sides of the flex configuration

Reduced assembly costs due to minimized interconnect errors

Dynamic flexing ability

Production-quality flex and rigid flex prototypes and small-to-medium-production at quick-turn speeds. Leading-edge technologies to fabricate your designs to validate concepts to production.

Enquire

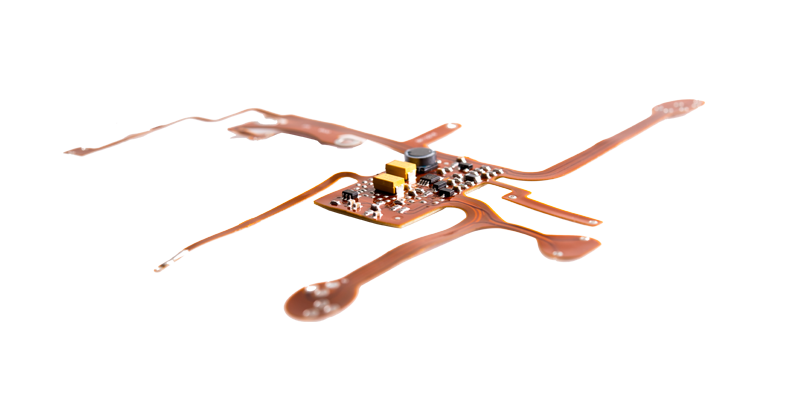

Single-sided flex circuits are the most basic type of flexible circuits, durable across applications and are excellent for installations in small spaces.

Learn More

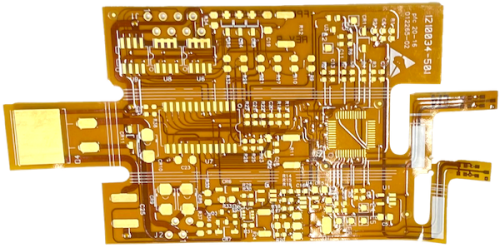

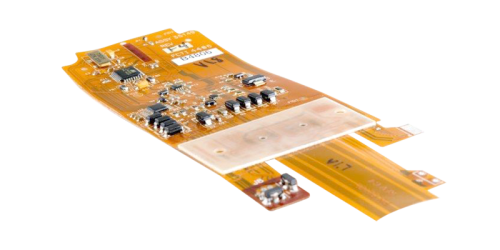

Multi-layer flexible circuits combine several single-sided or double-sided circuits with complex interconnections, shielding and/or surface mounted technologies in a multi-layer design.

Learn More

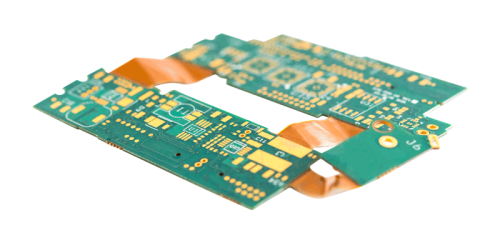

Rigid flex circuits combine the benefits of rigid boards and flexible circuits integrated into one circuit.

Learn More

Sculpted flexible circuits have sculpted pins, often chosen to eliminate the need and cost of a ZIF connector.

Learn More

PFC has created the PFC High Speed Data Link Flexible Circuits product line, in collaboration with Samtec.

Learn MoreProduction-quality flex and rigid flex prototypes and small-to-medium-production at quick-turn speeds. Leading-edge technologies to fabricate your designs to validate concepts to production.